Digital Oil Field of the Future

The efficiency of digital oil field can be compared with the revolutionary effect of using advanced control and automation technology in space industry around 1960s. Simply, in a digital oil field conditions of different parts of an oil and gas production system both surface and subsurface are monitored continuously and the data is stored. The data is used then to evaluate the performance of each equipment according to a desired operation condition. Another very important parts of this system are the actuators in different levels of the system acting and affecting the operation based on the issued control commands. These actuators affect the system in the sandface of the reservoir and the surface facilities and the connected pipelines.

Apart from the inherent necessary equipment in digital oil field, different levels of intelligence in such system can be designed and implemented. These levels starts from the very low level of instrumentation to the top level of an autonomous system however nowadays the first level has been deployed by many IOCs in their strategic fields.

History and current status of intelligent fields

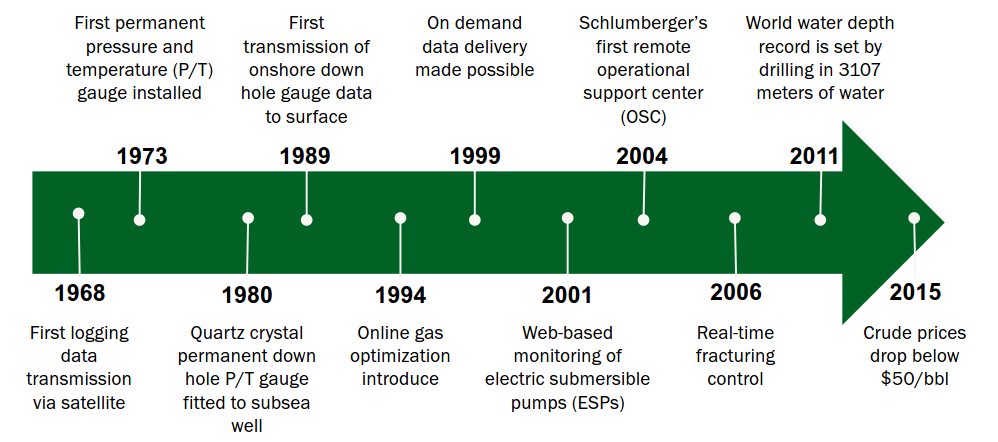

Around 1960s first permanent downhole pressure gauges in Gabon was installed and after that great and continuing development in the field of durable and robust sensors has been occurred. Figure 2 shows a time-line graph of the development in sensor technology in E & P industry. Parallel to this, the need to control the flow in horizontal and other complex wells in thin reservoirs and other similar challenging production formations, force the service companies to develop appropriate downhole valves that can control the opening interval of the formations in the wellbore in a real-time fashion. Integration of the sensor and actuator technologies formed the basis of a complete smart well later completed with SCADA systems and data management technology to form digital or intelligent field.

In today’s oil and gas industry many of the pioneered companies have adopted using the concept of intelligent field. BP started this endeavour with its Fields of the future® program started in 2002. Shell’s Smart field® has reportedly gained around $5 Billion from 2002 to 2009. Statistics shows the number of smart fields are around 180, smart well exceeds 1000 wells and more than 10000 well have been equipped with permanent downhole sensors.

Figure 2: Smart well technology development history.

Source: http://www.boozallen.com

Strategic effect of digital oil field

Accounting for the full value chain in E & P, it shows that different segments are affected differently from implementing the technology. Figure 3 demonstrates this and shows that in the production phase the greatest impact is occurred.

Figure 3: DOF affects different segments of E&P differently.

Source: http://www.mckinsey.com

Economic analysis results on real experiences of the operator companies shows a 25% increase in NPV of E & P projects using DOF technology. Automation decreases the needs to skilled workforces in harsh environments. Statoil could decreases the staffs on an offshore production plant by 25% after implementing the technology. It is estimated that the market of this technology till 2024 will be around $28.5 B.

Dr. Mehdi Mansouri

Executive Vice President

We Answer Your Questions